|

|

|

|

|

|

Operator friendly monitor Operator friendly monitor

All your necessary information displayed at a moment's notice, quick and easy

Simple product changeover

1. Confirm product details and setup details

2. Select pre-programmed product code

3. Load casings and push the start button

|

Everything is stored and pre-determined. LInker- and pump speed, casing control, twist etc... the same every time!!

Maintenance and troubleshooting:

If any type of problems occur during operation, its location will be displayed immediately. Also, it can quickly be resolved with a flow chart for the machine. |

|

|

|

|

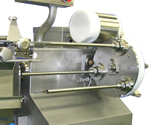

| This system reduces the number of operators when stuffing natural casing

sausages. During the linking process, the casing is being advanced forward

through the follower mechanism. Once the casing comes to the end, the linker

stops, follower retracts and allows the reloading of the next casing. This

all happens automatically without human intervention. |

|

|

|

|

|

Multi type casing round bar hook Natural casing plate hook

|

Other hook designs available for ring sausage or other specialized applications.

|

|

|

|

|

The multi stuffing tube turret (revolver head) allows:

- pre-feeding of natural casings

- up to 20% increased production output

- faster cycle times

- reduced machine stopping / waiting time |

Comparison between standard one tube linker and MACHWEL- MKⅢ with revolver

head |

|

One tube linker |

Revolver head |

| Stuffing Tube |

1 |

3 |

Average

Operation Rate |

55% |

65% |

| Production / hour |

300 kg / 660 lbs |

420 kg / 925 lbs |

|

|

|