|

|

| |

|

|

|

| If any type of problems occur during operation, its location will be displayed immediately. Also, it can quickly be resolved with a flow chart for the machine. |

|

|

|

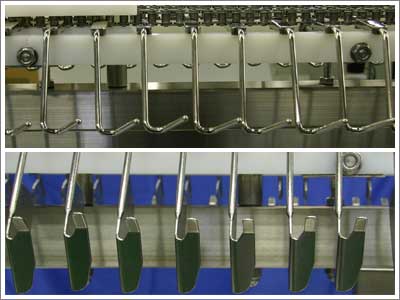

Bottom : Natural casing plate hook |

|

|

|

| Production Rate | Artificial Casing | Ask. |

|---|---|---|

| Natural Casing | Ask. |

※Dependent on casing quality, product size, weight and/or factory conditions.

| Product Size | Artificial Casing | 3 pitches (28.6 mm, 1 1/8 in) through 32 pitches (304.8 mm, 12 in) or more. |

|---|---|---|

| Natural Casing | 3 pitches (28.6 mm, 1 1/8 in ) through 20 pitches (190.5 mm, 7 1/2 in) or more |

※Longer sizes can be applied with HITEC'S optional unit.

| Casing Size | MACHWEL-MARKⅢ | ||

| Diameter | Sheep Casing | 14 mm ~ 25 mm | |

| Hog Casing | 26 mm ~ 36 mm | ||

| Artificial Casing | 13 mm ~ 32 mm | ||

| Shirred Length | Artificial Casing | 280 mm, 11 1/32 in 300 mm, 11 13/16 in | |

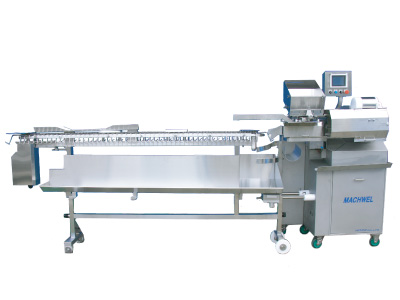

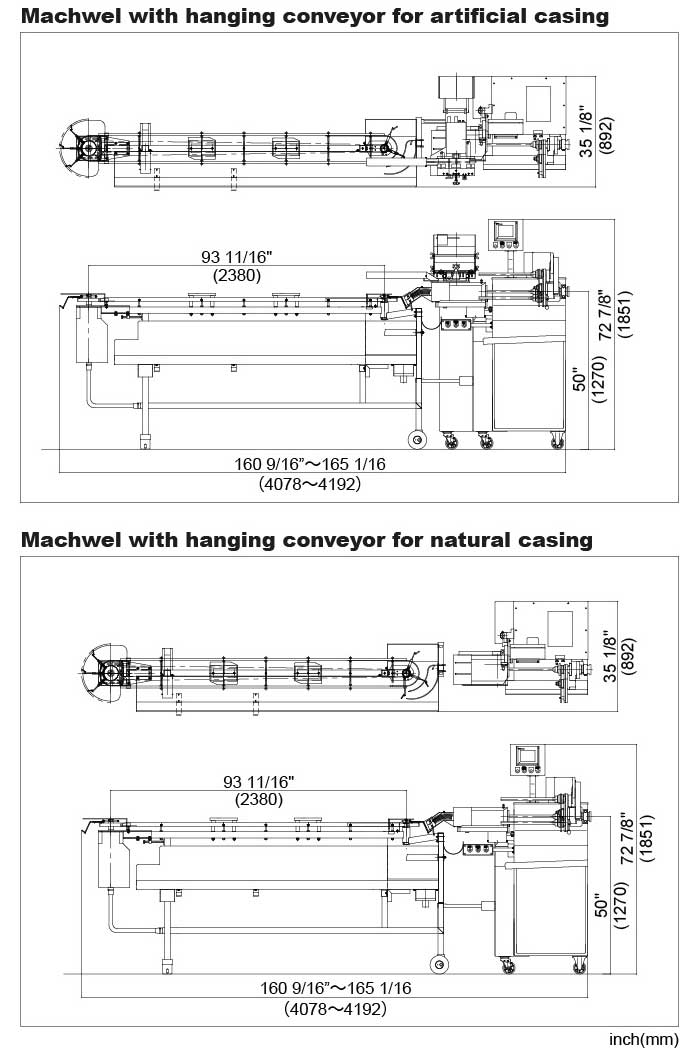

| Total Machine size | MACHWEL - MARKⅢ | Hopper for Artificial Casing | 8 F conveyor |

|---|---|---|---|

| Height | 1851 mm | 1727 mm | 1320 mm |

| Tube height | 1270 mm | 1270 mm | 1270 mm |

| Length MAX | 1195 mm | 904 mm | 2999 mm |

| Width | 817 mm | 870 mm | 795 mm | Weight | 400 kg | 50 kg | 190 kg |

| Electrical Requirements | Three-Phase 6,775 W | ||

|---|---|---|---|

| Pneumatical Requirements | Quality | clean and dry | |

| Pressure | 520 kPa (5.2 bar) 75 psi | ||

| Consumption | 1 L, (1,000 cm3) per min 60 in3 per min | ||

| Water Requirements | Quality | clean and drinkable water | |

| Pressure | 280-410 kPa (2.8-4.1 bar) 40-60 psi | ||

| Consumption | 1 L, (1,000 cm3) per min 60 in3 per min | ||

| Emulsion Requirements | Pressure | 500 kPa (5 bar) 75 psi | Consumption | Max. 3,200 kg/hr Max. 7,000 lb/hr |

| Piping | Largest diameter and shortest length | ||

---------------- Contact us!----------------

| HEAD OFFICE 2565-8, Nagatsuta-cho, Midori-ku, Yokohama, 226-0026, JAPAN ▶ Contact us by phone TEL +81-45-983-5000 FAX +81-45-983-0020 ▶ Contact us by online |

CATALOG Download |

|---|

![]()

![]()