|

|

| |

|

|

|

| |

|

|

|

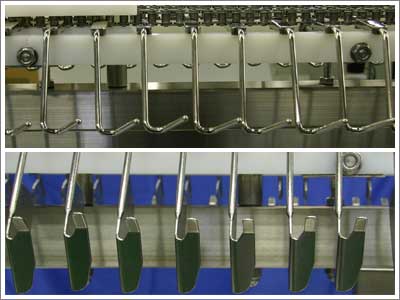

Bottom:Natural casing plate hook |

|

|

|

| Production Rate | Artifical Casing | Ask. |

|---|

※Dependent on casing quality, product size, weight and/or factory conditions.

| Product Size | Artifical Casing | 3 pitches (28.6 mm , 1 1/8 in) through 32 pitches (304.8 mm , 12 in )or more |

|---|

※Longer sizes can be applied with HITEC'S optional unit.

| Casing Size | HITEC M-10 | HITEC M-20 | |

| Diameter | Collagen Casing | 13 mm (33/64 in) ~ 32 mm (1 17/64 in) | |

| Cellulose Casing | 14.5 mm (37/64 in) ~ 34 mm (1 11/32 in) | ||

| Shirred Length | Collagen Casing | 280 mm (11 1/32 in) | 300 mm (11 13/16 in) |

| Cellulose Casing | 325 mm (12 25/32 in) | 440 mm (17 5/16 in) | |

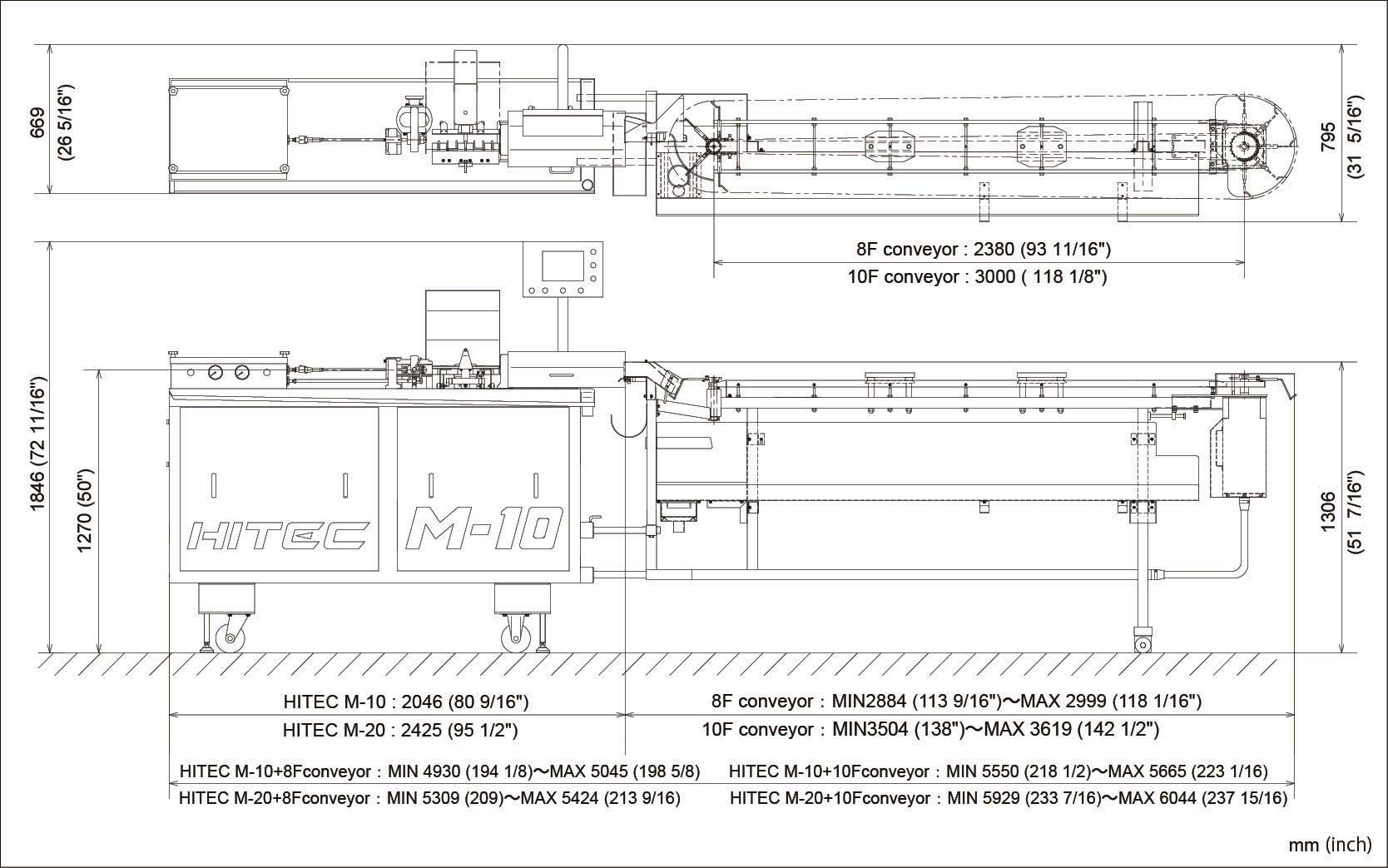

| Total Machine Size | HITEC M-10 + 8F conveyor |

HITEC M-20 + 8F conveyor |

HITEC M-10 + 10F conveyor |

HITEC M-20 + 10F conveyor |

|---|---|---|---|---|

| Height | 1846 mm (72 11/16 in) | 1846 mm (72 11/16 in) | 1846 mm (72 11/16 in) | 1846 mm (72 11/16 in) |

| Tube height | 1270 mm (50 in) | 1270 mm (50 in) | 1270 mm (50 in) | 1270 mm (50 in) |

| Length MAX | 5045 mm (198 5/8 in) | 5424 mm (233 7/16 in) | 5665 mm (223 1/16 in) | 6044 mm (237 15/16 in) |

| Width | 795 mm (31 5/16 in) | 795 mm (31 5/16 in) | 735 mm (28 15/16 in) | 735 mm (28 15/16 in) | Weight | 690 kg (1518 lb) | 730 kg (1610 lb) | 710 kg (1562 lb) | 750 kg (1650 lb) |

| Electrical Requirements | Three-Phase 6,775 W | ||

|---|---|---|---|

| Pneumatical Requirements | Quality | clean and dry | |

| Pressure | 520 kPa (5.2 bar) 75 psi | ||

| Consumption | 1 L, (1,000 cm3) per min 60 in3 per min | ||

| Water Requirements | Quality | Clean and drinkable water | |

| Pressure | 280-410 kPa (2.8-4.1 bar) 40-60 psi | ||

| Consumption | 1 L, (1,000 cm3) per min 60 in3 per min | ||

| Emulsion Requirements | Pressure | 500 kPa (5 bar) 75 psi | Consumption | Max 3,200kg/hr Max 7,000 lb/hr |

| Piping | Largest diameter and shortest length | ||

---------------- Contact us!----------------

| HEAD OFFICE 2565-8, Nagatsuta-cho, Midori-ku, Yokohama, 226-0026, JAPAN ▶ Contact us by phone TEL +81-45-983-5000 FAX +81-45-983-0020 ▶ Contact us by online |

CATALOG Download |

|---|

![]()

![]()