| VACUUM LINKWEL MOVIE |

|---|

|

|

| |

|

|

|

| |

|

|

|

| |

|

| Production Rate | Collagen Casing | Max. 2,000 pcs./min |

|---|---|---|

| Cellulose Casing | Max. 3,000 pcs./min | |

| Natural Casing | Max. 1,000 pcs./min |

※Dependent on casing quality, product size, weight and / or factory conditions.

| Product Size | Collagen Casing | 2 cm (25/32 in) through 32 cm (12 19/32 in) or more. |

|---|---|---|

| Cellulose Casing | 2 cm (25/32 in) through 32 cm (12 19/32 in) or more. | |

| Natural Casing | 3 cm (1 3/16 in) through 22 cm (8 21/32 in) or more. |

※Longer sizes can be applied with HITEC'S optional unit.

| Casing Size | VACUUM LINKWEL | VACUUM LINKWEL-L | |

| Diameter | Sheep Casing | 14 mm (35/64 in) ~ 25 mm (63/64 in) | |

| Hog Casing | 26 mm (1 1/32 in) ~ 36 mm (1 27/64 in) | ||

| Collagen Casing | 13 mm (33/64 in) ~ 36 mm (1 27/64 in) | ||

| Cellulose Casing | 13 mm (33/64 in) ~ 40 mm (1 37/64 in) | ||

| Shirred Length | Collagen Casing | 320 mm (12 19/32 in) | 320 mm (12 19/32 in) |

| Cellulose Casing | 355 mm (13 31/32 in) | 440 mm (17 21/64 in) | |

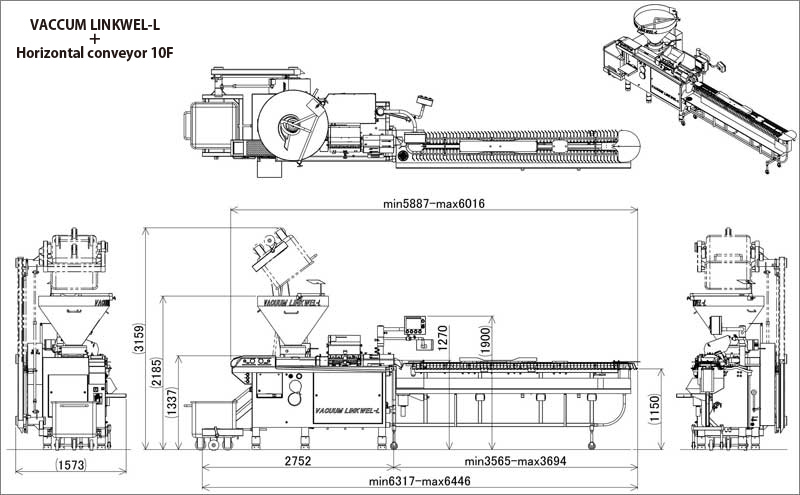

| Total Machine size | VACUUM LINKWEL + Horizontal conveyor | VACUUM LINKWEL-L + Horizontal conveyor |

|---|---|---|

| Height | 2047 mm (80 19/32 in, Low) / 2185 mm (86 1/32 in, High) | |

| Tube height | 1133 mm (44 39/64 in, Low) / 1270 mm (50 in, High) | |

| Length MAX | 8F / 5546 mm (228 11/32 in) 10F / 5956 mm (234 31/64 in) |

8F / 5579 mm (219 41/64 in) 10F / 6446 mm (253 25/32 in) |

| Width | 1573 mm (61 59/64 in) | Weight | 8F / 1530 kg (3373 lb) 10F / 1550 kg (3417 lb) |

8F / 1630 kg (3594 lb) 10F / 1650 kg (3638 lb) |

| Hopper Capacity | 300 L | |

| Net (Machine dimension and weight) | VACUUM LINKWEL | VACUUM LINKWEL-L | Horizontal conveyor 8F | Horizontal conveyor 10F |

|---|---|---|---|---|

| Height | 2047 mm (80 19/32 in, Low) 2185 mm (86 1/32 in, High) |

1205 mm (47 7/16 in, Low) 1345 mm (52 61/64 in, High) |

Length MAX | 2719 mm (107 3/64 in) | 2752 mm (108 11/32 in) | 3050 mm (120 5/64 in) | 3500 mm (137 51/64 in) |

| Width | 1573 mm (16 59/64 in) | 530 mm (20 55/64 in) | Weight | 1400 kg (3086 lb) | 1500 kg (3307 lb) | 130 kg (287 lb) | 150 kg (331 lb) |

| Electrical Requirements | Three-Phase 8,500 W | ||

|---|---|---|---|

| Pneumatical | Pressure | 520 kPa (5.2 bar) 75 psi | |

| Consumption | 1 L, (1,000 cm3) per min 60 in3 per min | ||

| Water | Quality | Clean and drinkable water | |

| Pressure | 280-410 kPa (2.8-4.1 bar) 40-60 psi | ||

| Consumption | 1 L, (1,000 cm3) per min 60 in3 per min | ||

---------------- Contact us!----------------

| HEAD OFFICE 2565-8, Nagatsuta-cho, Midori-ku, Yokohama, 226-0026, JAPAN ▶ Contact us by phone TEL +81-45-983-5000 FAX +81-45-983-0020 ▶ Contact us by online |

CATALOG Download |

|---|

![]()

![]()