|

|

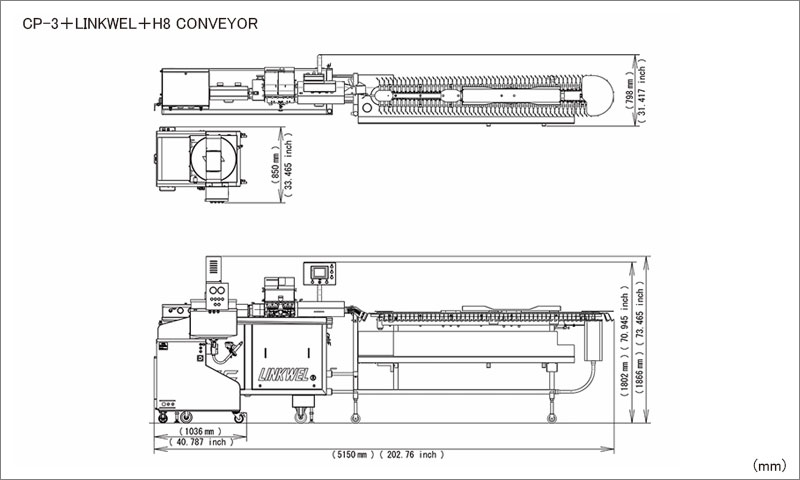

Taking CP-3 off of high speed linker, you can use only high speed linker. Both a general and a double layer sausage can be produced. |

|

|

|

|

|

Both a target temperature and the actual temperature on the monitor help the operators arrange the setting of temperature. An agitator in the hopper prevents the material from hardening. |

| Hopper capacity | 56 L |

|---|---|

| Discharge rate (30℃ or more) | 0.7 - 27 L / min |

| Speed range | 10 - 400 rpm (50 / 60 Hz) |

| Power requirements | 3.2 kW |

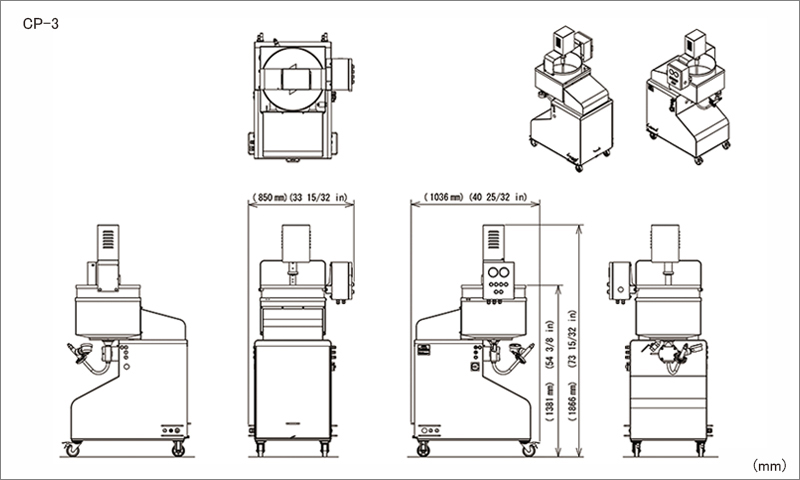

| Height | 1,866 mm (73 15/32 in) |

| Width | 850 mm (33 29/64in) |

| Length | 1,036 mm (40 25/32 in) |

| Weight | Approx 330 kg (727.52 lb) |

---------------- Contact us!----------------

| HEAD OFFICE 2565-8, Nagatsuta-cho, Midori-ku, Yokohama, 226-0026, JAPAN ▶ Contact us by phone TEL +81-45-983-5000 FAX +81-45-983-0020 ▶ Contact us by online |

CATALOG Download |

|---|

![]()

![]()